Designing for Mission Success

Every successful product starts with robust requirements. At AI Zerocaliber, our hardware design process is a disciplined, multi-stage methodology focused on performance, predictability, and production efficiency. We transform high-level requirements into detailed specifications that drive the schematic phase, ensuring optimal outcomes from day one.

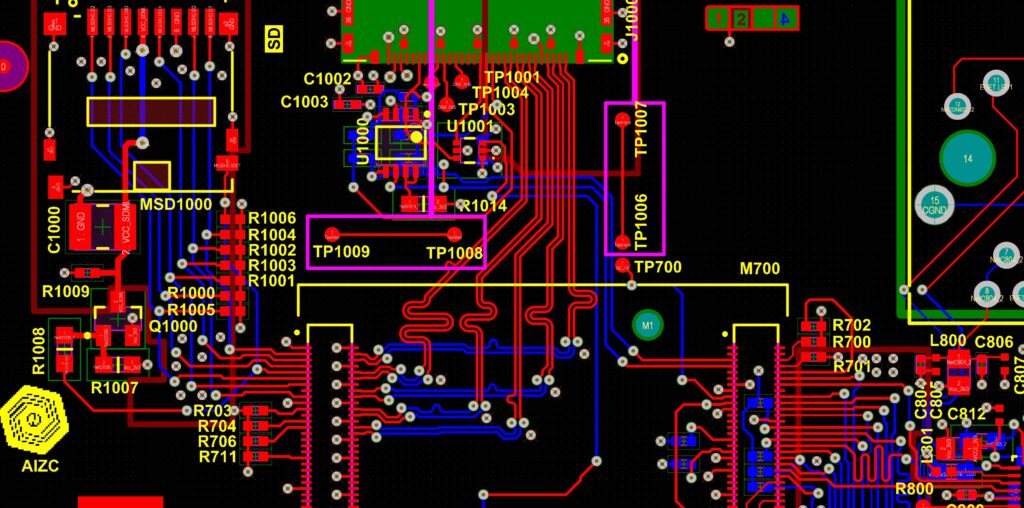

- High-Density Interconnect (HDI) Boards: We specialize in complex, multi-layered HDI boards, which are essential for minimizing physical size while maximizing computational density. This capability enables smaller, lighter, and faster products—a critical advantage in space and demanding industrial applications.

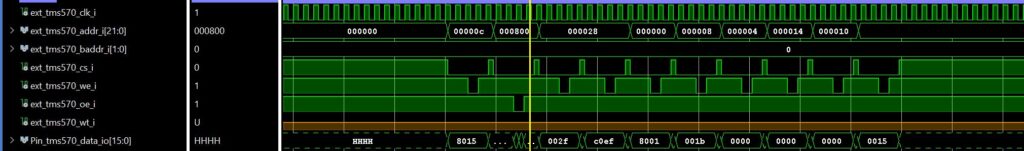

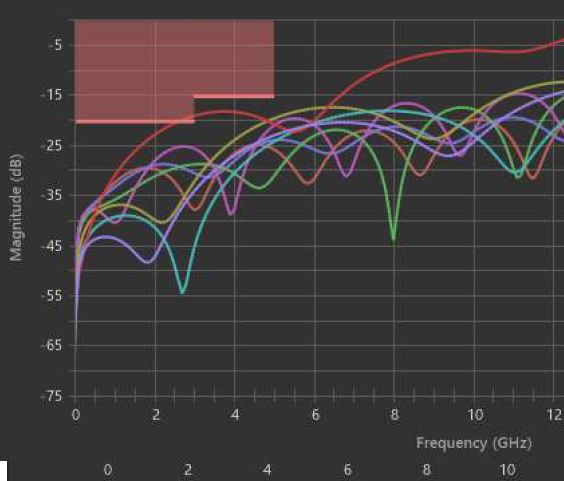

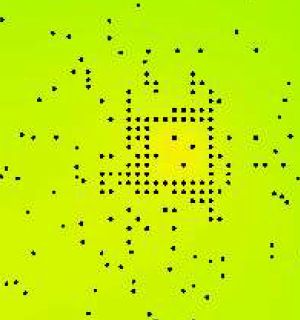

- Signal Integrity (SI) Simulations: We rigorously perform Signal Integrity (SI) Simulations to predict and mitigate high-speed signal issues such as reflections, crosstalk, and timing errors before manufacturing. This step is mandatory to ensure clean, reliable data transmission at speed.

- Power Delivery Network (PDN) Simulations: We conduct detailed Power Delivery Network (PDN) simulations to guarantee stable and efficient power delivery across the board. This is vital for complex devices like FPGAs and microcontrollers, ensuring they receive clean, consistent power to operate reliably under all load conditions.

- Provisions for Test: We integrate provisions for selected test strategies directly into the board design. Depending on technology and quantity, this includes features for Functional Test, JTAG/Boundary Scan, and other custom testing methods.

- Deep Domain Experience: Our hardware experience spans the full product lifecycle, from initial specifications to long-term product support, covering critical systems involving DC motors, sensing platforms, Microcontrollers, FPGAs, and seamless mechanical integration.

- Documentation: This part is often neglected from non-experienced teams but is necessary for product continuity, its support by other teams (ie. software) and avoid future unnecessary architectural changes from new teams given that these has been already analyzed and reviewed during the design process.

- Strategic Component Selection: We meticulously select parts based on technical fit, high availability, and low-risk lead times. We also consider component packages carefully, balancing PCB area requirements with assembly process efficiency to control costs.

- Design for Manufacturability (DFM): We possess a deep understanding of PCBA production phases. This knowledge allows us to design an efficient PCB that can be produced smoothly and reliably in quantities without disruptions, avoiding the higher manufacturing classes and cost escalations associated with inefficient density.

- Risk Mitigation: Poor decisions in these early stages can quickly lead to budget overruns and missed time-to-market advantages—the common failure point for many kick-start projects. Our experienced approach eliminates this uncertainty.

Advanced Design and Integrity

Our expertise goes beyond conventional PCB layout to address the complexities of high-speed and high-density systems:

Integrated Testing and Lifecycle Support

Production is not the final step; guaranteed reliability requires thorough verification.

We utilize top-of-the-line CAD tools (Altium Designer) to tackle all these aspects of product design and lifecycle maintenance, further leveraging strong collaboration capabilities to enhance documentation, change control, and design reviews.

Component Lifecycle and Production Mastery

An often-neglected yet critical factor is the long-term viability of the electronic design. We mitigate risks through:

FPGA Development

For more demanding applications we support FPGA development as a solution for edge processing and hardware acceleration. From RTL (VHDL) code to final implementation and timing closure we finish the design cycle to the bench were the design is verified against the specifications.